| Product name | Biobased content (%) | EEW (g/equ.) | Viscosity at 25 °C (mPa·s) | Description | Application |

| Epilox® A 18-00G | 28 | 175 - 185 | 45207 | Bisphenol A resin, low viscosity | General purpose epoxy resin |

| Epilox® A 19-00G | 28 | 182 - 192 | 41518 | Bisphenol A resin, medium viscosity | General purpose epoxy resin |

| Epilox® A 17-01G | 28 | 171 - 176 | max. 6 | Bisphenol A resin (high-purity resin) | Potting and sealing in electrical and electronic applications |

Discover the future of bio-based products with LEUNA-Harze

LEUNA-Harze's bio-based epoxy resin process is a beacon of sustainability in the industry

By utilizing renewable resources and own produced raw materials, the production of these biobased epoxy resins and reactive diluents significantly reduce the carbon footprint. This innovative approach is a major step forward from traditional petroleum-based methods, offering a greener and more responsible choice for the industry. Our commitment to sustainability doesn’t end with the product; our manufacturing process is also designed to minimize environmental impact, making LEUNA-Harze a leader in eco-friendly industrial solutions.

Glycerin process

The glycerin transformation process employed by LEUNA-Harze GmbH is not only designed for efficiency and sustainability but is also integral to the production of chlorine, hydrogen, hydrochloric acid, and sodium hydroxide. This comprehensive method seamlessly combines electrolysis with internal epichlorohydrin (ECH) synthesis, effectively converting bio-based glycerin in a more eco-conscious manner. Harnessing steam energy and utilizing sodium chloride and waste materials, this approach yields vital components necessary for various products, particularly bio-based epoxy resins and reactive diluents.

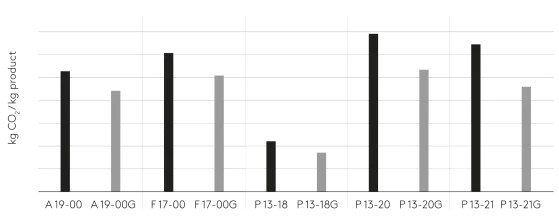

CO₂ footprint

Bio-based production

Utilizing bio-based Epichlorohydrin for Epilox® products effectively curtails CO₂ emissions in the manufacturing process. This eco-friendly method aligns with our dedication to sustainable practices.

Optimized technology

Optimized technology and efficient manufacturing practices are integral to lowering overall CO₂ emissions associated with traditional Epilox® products. This commitment to optimization underscores our ongoing efforts to enhance process eco-friendliness.

Renewable energy integration

Incorporating sustainable energy sources in the production process to further reduce the amount of CO₂ emitted, demonstrating a commitment to environmental responsibility.

Epilox® A & F series

The Epilox® A & F series stands out with its bio-based carbon content in Bisphenol A and Bisphenol F resins, ideal for a wide range of industrial applications. These resins also exhibit exceptional crystallization resistance.

Bisphenol A - resin

Bisphenol F - resin

| Product name | Biobased content (%) | EEW (g/equ.) | Viscosity at 25 °C (mPa·s) | Description |

| Epilox® F17-00G | ~30 | 165 - 173 | 2.5-4.5 | Bisphenol F resin |

Epilox® T19

The Epilox® T19 series takes it a step further, combining the strengths of A resin (Epilox A19-00G) and F resin (Epilox F17-00G). The T19 series introduces variations in viscosity, providing users with a broader spectrum of options to suit specific application needs.

Bisphenol T - resin

| Product name | Biobased content (%) | EEW (g/equ.) | Description |

| Epilox® T 19-34 series | up to 34 | 165 - 180 | Bisphenol A/F resin, with reactive diluent |

| Epilox® T 19-36 series | up to 41 | 190 - 210 | Bisphenol A resin, with reactive diluent |

| Epilox® T 19-38 series | up to 41 | 180 - 200 | Bisphenol A/F resin, with reactive diluent |

Bio-based reactive diluents

The Epilox® P series offers specialized bio-based reactive diluents tailored to meet diverse industrial requirements.

Epilox® P series

| Product name | Biobased content (%) | EEW (g/equ.) | Viscosity at 25 °C (mPa·s) | Description | Application |

| Epilox® P 13-18G | 100 | 270 - 305 | 5 - 10 | Monoglycidyl ether of C12-C14 alcohol, good dilution effect, weak flexibilization | Floorings, concrete repair, general-purpose diluent |

| Epilox® P 13-20G | 50 | 140 - 160 | 15 - 25 | Diglycidyl ether of 1,6-hexanediol, low volatility | Floorings, concrete repair, general-purpose diluent |

| Epilox® P 13-21G | 60 | 125 - 145 | 12 - 21 | Diglycidyl ether of 1,4-butanediol | Laminates, concrete repair, electrical applications |