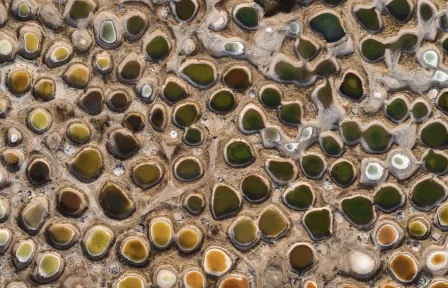

Formulated with PDMS (polydimethylsiloxane), these defoamers offer excellent knockdown and long-lasting foam control—even in high-pH and high-temperature environments. Ideal for industrial wastewater, but not recommended where silicone-sensitive processes or membrane filtration are involved

Q- FOAM

Foam happens... But the right response makes the difference!

Formulated as emulsions, dispersions, or blends, Q-FOAM products combine the best of silicone, organic, and mineral-based technologies to deliver reliable results across wastewater treatment, anaerobic digestion, plastics recycling, food processing, and more. Backed by expert guidance and adaptable to system conditions like pH, temperature, and biodegradability needs, Q-FOAM keeps your operations clean, controlled, and efficient.

Choose the rigt type of defoamer

Silicone-based defoamers

Oil-based defoamers

Heavy-duty performers for persistent and high-volume foam. These mineral oil formulations deliver strong defoaming power and good persistency, but are unsuitable for biological systems like anaerobic digesters due to biodegradability concerns

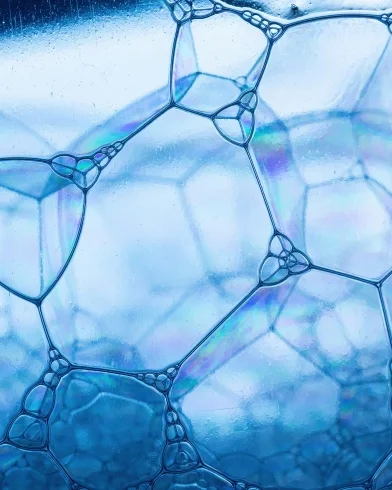

Water-based emulsions & dispersions

These defoamers disperse easily in water and are well-suited for environmentally sensitive or biological applications. They typically contain biodegradable actives and are commonly used in general wastewater treatment and the paper industry

Organic blend defoamers

Crafted from natural oils, waxes, surfactants, and polysaccharides, these blends balance foam control and sustainability. Their flexibility makes them suitable for applications requiring both performance and an eco-friendly profile